AP23490711 Experimental Investigation of Elastoviscoplastic Turbulent Flows in a Cylindrical Pipe

News and events

The project leader, S.O. Topaev, participated in the conference “Smart Agriculture, Bright Future: Implementation of Intelligence in Agriculture,” held on September 26–27, 2024, in Almaty, Kazakhstan. The event was organized by the Islamic Organization for Food Security. As part of the conference, he delivered a presentation on recent research regarding the application of modern intelligent technologies in the field of food security.

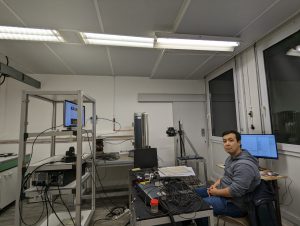

The experimental visit to the LEMTA laboratory was focused on setting up experimental equipment, calibrating measuring instruments, and conducting preliminary test experiments.

During the scientific visit, the final assembly and commissioning of the experimental setup for studying the flow of a yield-stress fluid in a horizontal pipe were completed. All components prepared in advance were integrated into a single test bench. A meticulous assembly of the optical measurement section was carried out; the pipeline was properly aligned, and all elements were securely fastened to an anti-vibration platform. Special attention was paid to ensuring system tightness and maintaining thermal stability in the environment. All necessary procedures for precise calibration of the measuring instruments were executed on-site.

Additionally, previously prepared samples of Carbopol solutions, whose rheological properties were characterized before the trip, were utilized. A repeated, rapid on-site viscosity test confirmed the stability of their properties.

In the final phase, test experiments were conducted with the aim of verifying the proper registration of velocity profiles and the overall functionality of the system. A solution with a concentration of 0.08% was introduced into the pipe, and axial profiles were recorded using the PIV method under a series of pressure gradients. The obtained data confirmed the anticipated flow characteristics: at a low pressure gradient, a central stagnant zone was observed, while an increase in the pressure gradient led to the formation of asymmetric oscillatory structures localized near the pipe wall. It was discovered that the instability modes exhibit temporal variability and spatial incoherence in the azimuthal direction, indicating the complex dynamics of the transitional flow.

The entire process concluded with full confirmation of the setup’s operability. Typical flow patterns were recorded, demonstrating sensitivity to pressure differences and the potential for transition from steady to unstable regimes. The results confirmed that the equipment is fully ready for the main series of measurements.