Project title: «Production of an extruder for plastic recycling» (project duration 12 months, 2021-2022).

Summary:

A breakthrough in the technology of production of polymer products threatens to turn into a real environmental disaster. Despite the advantages of plastics, they have one drawback: polymer materials synthesized on the basis of hydrocarbons are not biodegradable. Thus, polyethylene can be preserved in the soil for more than 100 years, and the decay time of modified polymers can be estimated only theoretically. Based on this, the problem of polymer recycling, which makes it possible to reuse plastics, is particularly relevant.

So, among the most important and indisputable advantages of self-designed devices for processing plastic thread, you can undoubtedly list the following:

- A significant reduction in the costs that are allocated for consumables for printing in 3D format;

- Thread can now be made from any available or desired type of plastic;

- You can mix different types of plastic in the manufacturing process, and then you will get a unique filament in its characteristics;

- And when experimenting with a combination of different colors and shades of plastic, you will get your own special color set to create unique printed materials;

- The ability to recycle an unsuccessful result of the printer will allow you not to throw money in the trash to buy it, but to re-use it for the same purpose, after recycling.

Relevance. One of the constraints to the development of FDM printing is the relatively high cost of consumables. Although most plastics are quite affordable for an ordinary user, the difference between the raw material and the finished thread is very significant – often the cost of the bar exceeds the cost of pellets of similar weight by tens of times. Thus, it is necessary to create portable, desktop devices for home production of thread from pellets and plastic waste.

Such installations can significantly reduce the cost of printing and, of course, improve the environment.

Project goal:

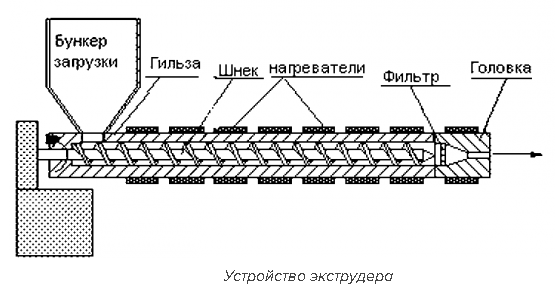

The goal is to create a special device for forming a molten polymer mass with further use for 3D printing.

Expected results:

The amount of recycled thermoplastics using extruders is growing from year to year. Now the market has a situation in which the demand for processing exceeds the supply. This means that the conditions for further commercialization have been created! The expected results are the development and further operation of the extruder, obtaining a patent for a utility model, as well as the commercialization of this device.

Project Manager:

Akhmetov Zhalgas, Director of the IT Center of the Faculty of Natural Sciences, Master of Pedagogical Sciences, Senior Lecturer. More than 15 scientific papers have been published in the databases of CQAFES, RSCI, in international conferences, and 4 textbooks have been published.

Research team members:

Kabdualiev Dastan, teacher of the Department of Mathematics and Computer Science, Master of Pedagogical Sciences. More than 5 scientific papers have been published in the CQAFES and RSCI databases, as well as in international conferences.

Kulyntaeva Asel, programmer of the IT Center of the Faculty of Natural Sciences, Bachelor of Engineering.

Scientific internships and advanced training:

- Akhmetov Zh. Belarusian State University, 2-week internship, Minsk, Republic of Belarus.

- Akhmetov Zh. Monthly internship at the Center of Secondary, Secondary – Special and Higher Education, Tashkent, Republic of Uzbekistan.

- Kabdualiev D. Three-month training at the Czech Agrarian University, Prague, Czech Republic.